The Missing Link?

IBM’s Watson technology bridges gap between supply chain risk management and big data

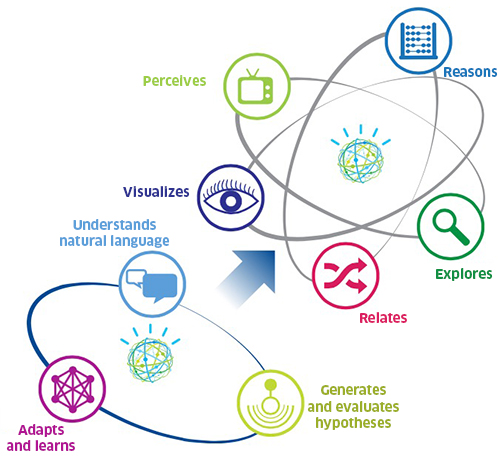

In the five years since IBM’s Watson bested reigning Jeopardy champ Ken Jennings to become the undisputed king of trivia; cognitive computing technology has evolved into one of the most significant technological change agents of the generation. Applications of Watson’s natural language processing, human-like ability to learn, real-time processing capacity and AI (augmented intelligence in IBM parlance) have upended “business as usual” strategies and processes across a swath of industries and disciplines, from healthcare and education to its most recent beneficiary – supply chain management.

With the introduction earlier this year of Watson Supply Chain, IBM is “changing the paradigm of how manufacturing supply chains are operated and optimized,” noted Simon Ellis, program vice president, Supply Chain Strategies, IDC, in a blog following the launch of Watson Supply Chain at the inaugural World of Watson expo. “At IDC, we have talked about manufacturing companies having an ‘analytics gap’ wherein analytics capabilities fall behind the explosive growth rate of available data; but there is also an ‘eyeballs gap’ with global supply chains simply not having adequate personnel to provide next best action to potential risks and disruptions,” Ellis wrote. “IBM’s Watson Supply Chain is the first comprehensive offering that we have seen that proposes to address both of these gaps.”

Do You See What I See?

Among the first capabilities being offered through Watson Supply Chain is an advanced risk alert and resolution feature called Watson Supply Chain Insights (WSCI), a commercialization of the proprietary cognitive computing technology that underlies IBM’s internal “Supply Chain Risk Insights powered by Watson” threat visualization tool. While both tools combine cognitive and cloud computing with big data analytics to improve visibility into physical and digital supply chains and provide supply chain leaders with predictive guidance, WSCI currently includes an abridged subset of the full in-house Risk Insights solution.

Tom Ward

“Right now, our internal capability is the pioneer for the external offering,” explained Tom Ward, cloud strategy leader for IBM Enterprise Services. He noted that it will take some time before WSCI picks up all the breadth of functionality in Risk Insights, which is the culmination of more than seven years of process and technology advancements within IBM. Each iteration of the internal procurement and production risk management tool leveraged the best technologies available at the time to wring more – and better – intelligence from the plethora of data resident within IBM’s expansive supply chain ecosystem, said Louis Ferretti, project executive for IBM’s Product Environmental Compliance and Supply Chain Social Responsibility.

“Cognitive computing technology has evolved into one of the most significant technological change agents of the generation.”

Lou Ferretti

The journey has taken the company from manually searching for information on potential disruptions (natural disasters, social and political unrest, pandemic disease and labor strikes) and conducting basic supplier risk assessments (financials, single/sole sourced, etc.) to employing Watson’s massive computing power and artificial intelligence capabilities to analyze terra bytes of data and distribute these data sets, at scale, in real-time, Ferretti noted. With these insights, IBM is able to more proactively mitigate risk and optimize its massive supply network, which today spans 17,000 suppliers across 100+ global markets and accounts for $30 billion in direct and indirect spend.

Behind the Curtain

Supply Chain Risk Insights includes application program interfaces (APIs), Watson Explorer, Natural Language Classifier and Alchemy Data News, and is further supported by the supply chain risk management and analytics functionality from Resilinc Corp. Since climatic events (storms, etc.) tend to be the dominant source of disruptions throughout IBM global supply network, Ferretti noted, the company has taken a particularly keen interest in tracking weather, as was demonstrated by its acquisition of The Weather Channel’s historical forecast data and analytics databases in October 2015. While the purchase baffled many at the time, IBM’s end game has become clear. TWC’s data provides IBM’s risk analysts a deeper view into meteorological data, improved forecasting capabilities and a technology platform that analyzes and distributes enormous amounts of real-time data sets. Risk Insights consumes TWC Data-as-a-Service (DaaS), allowing users to integrate historical and real-time weather data, roll it up to a cloud-based application and get detailed visualizations of what supply chain operations will be affected, explained Ward.

Other data sources for Risk Insights include IBM’s internal enterprise systems, real-time reports from the Global Disaster Alerts and Coordination System (GDACS), Twitter feeds from the National Hurricane Center as well as an assortment of unstructured data sources, including news feeds, social media, videos and trading partners’ systems. Risk Insights monitors and displays the trajectory of each named storm, alerts risk analysts when these intersect with locales in which IBM or its partners maintain operations, and provides a quick comparison of the current storm with previous events in the region.

As valuable as it is to know when or if a storm will make landfall, true empowerment comes with IBM’s ability to overlay all the available weather data onto supply chain data produced from monitoring 2000 supplier and IBM locations. Having more accurate and timely information about which customers, suppliers, factories or products will be impacted, and what the cost of the impact will potentially be, creates “all sorts of competitive advantages,” said Ferretti.

“Risk Insights consumes TWC Data-as-a-Service, allowing users to integrate historical and real time weather data, roll it up to a cloud-based application and get detailed visualizations of what supply chain operations will be affected.”

From Computing to Collaborating

The Risk Insights solution also goes beyond monitoring and reporting. With machine-learning capabilities and IBM’s Bluemix cloud connectivity, this data is turned into relevant insights such as estimated time delays, projected financial costs and alternative sources that give risk analysts a deeper understanding of a risk’s impact and accelerate decision making. When a situation arises, Watson can even recommend specific internal subject matter experts to gather in a virtual workroom, called the Resolution Room, to quickly solve the problem. The team may ask Watson, “Which other suppliers compare with our main supplier?” Instantaneously, Watson may respond with two suppliers who have the product in question, along with helpful specifics such as supplier location and pricing.

This scenario reinforces IBM’s long-term corporate mantra that AI’s greatest promise is not in replacing humans, but in working collaboratively to augment the individual’s capabilities. “The more information we have and the earlier we get this information, the better next-step decisions we can make,” said Ferretti. Big-data analytics enable companies like IBM to be able to plan a few days ahead, instead of just a few hours. “That means we may be able to secure enough supply before a disruption occurs or find another way to source parts or move inventory around.” With Watson on the job, “we know there is an eye on the ball all the time now,” Ferretti said. “We also now have a uniform methodology and a way to capture data, analyze it and point out what we need to pay attention to. This should definitely help me sleep better.”

“AI’s greatest promise is not in replacing humans, but in working collaboratively to augment the individual’s capabilities.”

Go/No-Go

Though supply chain’s strategic role in enterprise growth and profitability is widely acknowledged today, controlling costs remains a core mandate for supply chain organizations.

“We needed to have a lot less of Chicken Little’s the-sky-is-falling types of worries and be able to act on the events that posed a real risk,” said Ward.

By leveraging Watson’s cognitive technologies to create a single, shared view of supply chain data and intelligence across an ecosystem of suppliers, partners, systems, and processes, IBM can not only react more quickly to potential disruptions and risks, but predict them with a degree of accuracy never before possible.

This precision allows IBM to put supply chain rules and exception-planning concepts into place, while delineating which weather conditions merit more or less attention. “The reality is, many, if not most, threats of disruption do not end up coming to fruition,” Ferretti noted. “Of the 150 or so recorded storms witnessed in the last couple of years, maybe only 10-12 of them truly raised the alert level. Taking preemptive actions such as qualifying another source, pulling inventory and/or moving the business to another supplier can lead to wasted time and resources if the threat fails to materialize.”

In recent years, IBM has had the opportunity to test its new risk tool on several occasions. When floods hit Chennai, India in November 2015, IBM analyzed the data and relocated workers temporarily to Bangalore, Ward said. During Hurricane Matthew, which went through the Caribbean and the Southeast coast of the U.S., Risk Insights was used to identify IBM suppliers at risk well in advance of impact using IBM’s The Weather Company (APIs). Likewise, recent Earthquakes in Italy, Japan and New Zealand have been closely monitored for supplier and IBM location impact using the proprietary threat visualization tool.

In recent years, IBM has had the opportunity to test its new risk tool on several occasions. When floods hit Chennai, India in November 2015, IBM analyzed the data and relocated workers temporarily to Bangalore, Ward said. During Hurricane Matthew, which went through the Caribbean and the Southeast coast of the U.S., Risk Insights was used to identify IBM suppliers at risk well in advance of impact using IBM’s The Weather Company (APIs). Likewise, recent Earthquakes in Italy, Japan and New Zealand have been closely monitored for supplier and IBM location impact using the proprietary threat visualization tool.

Leveraging Watson’s cognitive capability, IBM can create a single, shared view of the supply chain across an ecosystem of suppliers, partners, systems, and processes and predict potential disruptions with a degree of accuracy never before possible.

Not Just Lightning Strikes

As IBM’s risk management team continues to develop its ability to apply weather data to risk and supply chain management in a more calculated way, it is also examining what other disruptions can be curbed. Labor and transportation strikes are other factors, Ward and Ferretti said, adding that the company is in the early stages of building out the rules around how to respond to these events. By monitoring real-time social media and news feeds from credible sources about a pending strike, IBM’s cognitive supply chain program can filter out non-relevant information, start recognizing patterns and its risk management team can see where bottlenecks may occur.

In a recent report entitled The Cognitive Advantage: Insights from Early Adopters on Driving Business Value, IBM concludes “the cognitive era is here in large part because it makes practical business sense.” The study of over 600 early cognitive adopters found that procurement and supply chain operations were among the top five most cited functions reporting major competitive advantages from cognitive computing. And while cognitive computing is still a nascent market, it is poised to reach more than $31 billion in 2019, with an expected five year compound annual growth rate of 55 percent, according to IDC’s Worldwide Semiannual Cognitive Systems Spending Guide, published in early 2016.

“We live in a world with complex systems and complex interdependencies. Without a comprehensive way to analyze these complexities, they appear to behave unpredictably. With cognitive computing power, these unpredictable behaviors become predictable,” said Bindiya Vakil, chief executive officer and founder of Resilinc Corp., a provider of supply chain resilience and supply chain risk management intelligence and analytics. IBM and Resilinc are currently collaborating to enable the integration of APIs into Risk Insights that will extend IBM’s views into other types of risk and risk mitigation activities. “Risk is risk, but with accurate analytics we can reduce the time it takes to react to disruptive events.”

Related Resources

- IBM Watson Slideshare: What Every Procurement Professional Should Know About Supplier & Supply Chain Risk

- Study: Combating Risk with Predictive Intelligence

- White Paper: Ultimate Guide to Supply Chain Resiliency Program Success

- Event: World of Watson