AI as a Force for Good in Supply Chain Management

By Unni Nair

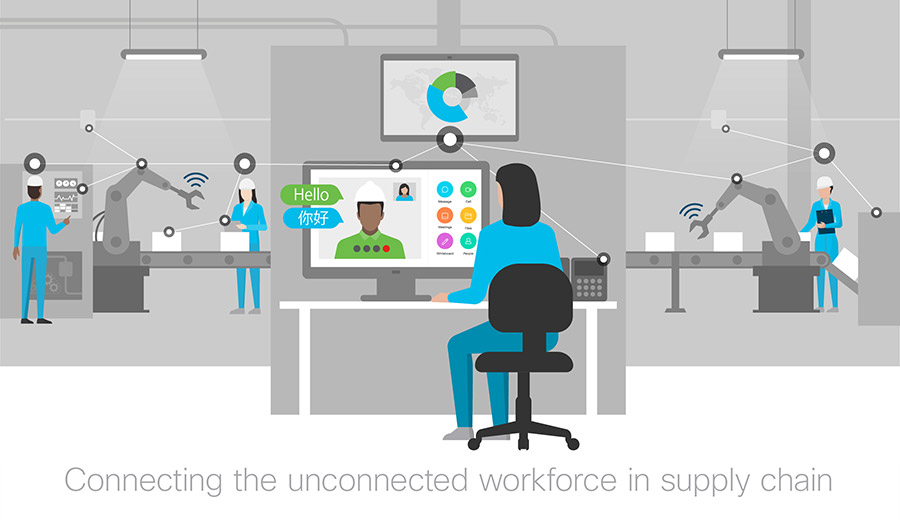

As artificial intelligence (AI) moves from research to reality, new insights and increasingly automated decision making are disrupting entire supply chain networks. AI will affect everything-from raw materials sourcing to factory floor productivity. These emerging technologies will unlock business value while simultaneously revealing opportunities to better utilize the workers within those ecosystems.

Emerging technologies such as AI and the Internet of Things (IoT) will help companies convert their data through intelligent, digital platforms to gain insights like never before. Supply chains will be able to correlate production level data alongside factory line compliance and performance. With this more complete view, companies and workers will be able to thrive at new levels by enabling faster and better decision making.

“By taking a human-centric approach to AI and technologies such as IoT, we can tap into workers’ knowledge and insight while also ensuring their fair treatment.”

Building a more intuitive supply chain network where the benefits of AI are both economically beneficial and societally inclusive will not be easy. As machines become capable of much of what makes us human, it will fall to businesses to embed our corporate values and codes of conduct into our supply chain tools to achieve business objectives. By taking a human-centric approach to AI and technologies such as IoT, we can tap into workers’ knowledge and insight while also ensuring their fair treatment.

With the introduction of these technologies, jobs are changing. Technical reskilling will be required to keep up with the rate of disruption. At the same time, more and more supply chain roles will also require creativity and values-driven decision making to complement expanding automation-those aspects of human nature that cannot be so easily computerized. The need for these attributes not only applies at the individual level, but also at the larger systems level, where corporate responsibility must go hand-in-hand with business outcomes.

Source: Cisco

At Cisco, we believe AI can be a powerful tool in the supply chain’s efforts to drive social and environmental responsibility (SER) improvements within our manufacturing operations. For example, using AI and next generation collaboration tools, like Cisco’s Webex Teams, our Supply Chain Operations team is developing technology to identify and address potential SER issues and provide actionable intelligence to drive the necessary corrective actions. This digital platform will ultimately translate across language, cultural and physical barriers and link auditors, Cisco, and our suppliers so that we may more effectively address corrective action plans (CAPs) for SER audits. Through our “CapBot” technology, our goal is to identify risks and vulnerabilities within factory lines. As the AI technology learns and adapts, it can inform decisions that drive real-time continuous improvements. The CapBot simplifies and automates routine tasks such as manual data collection, and it also ensures that supplier responsibility extends beyond compliance.

“AI can be a powerful tool in the supply chain’s efforts to drive social and environmental responsibility (SER) improvements.”

The increasing adoption of AI to automate many transactions in the audit process will enable brands like Cisco to focus on continuous improvement activities that can be machine aided over time. For example, surveys and trainings connected to audit findings can be sent over the platform with real-time click tracking mechanisms to ensure completion and test understanding. As our CapBot program expands, we expect to be able to develop metrics that will more accurately gauge the performance of our suppliers, which will help us to better assess risk and deploy appropriate resources.

We believe that this is just the beginning of what our supply chain will be able to accomplish as the implementation of AI matures. Think of the intelligence an organization might yield by connecting data from factory-level programs to understand the correlations between factory audit findings and manufacturing processes that improve the ability to identify and evaluate root causes and drive continuous improvement. Suppliers will be able to use AI to zero in on activities that drive systemic changes, such as adherence to multiple policies, to better manage both short and long-term risk or collaborate in areas such as digital reskilling.

“Through AI, workers and machines will be able to make better decisions in their supply chain roles, without compromising company values, or their livelihoods, in the name of the bottom line.”

For all the disruptive technologies emerging out of the digital industrial revolution, we should never forget that it is people who are at the center of every great advance in industry and society. Through AI, workers and machines will be able to make better decisions in their supply chain roles, without compromising company values, or their livelihoods, in the name of the bottom line. For Cisco, CapBot is the first step in our Supply Chain Operations’ journey toward that optimal human-machine engagement. As we progress and enable a more values-based, purpose-driven supply chain ecosystem, we encourage our suppliers, collaborators, and even our competitors, to embrace this brave new world, so that soon, we may all rest a little easier at night, knowing we have done our part to make the world a little safer, more fair and more prosperous for all.