Paul Keel, Senior Vice President of Supply Chain, 3M

SCN: You have held a number of executive management positions within 3M and other organizations. How does your experience of running a global supply chain differ from what you expected supply chain and its role in the business to be?

PK: “Growing up” in 3M, a vertically-integrated global manufacturer, I learned early on how central supply chain is to our company’s success. 3M manufactures roughly 85 percent of everything we sell. So the processes and technologies we use to produce and deliver our products must be as innovative as the products themselves. In fact, of the 100,000+ patents that 3M holds, roughly a quarter are for manufacturing process technologies. Having customer-facing roles prior to moving into supply chain helped me appreciate how much value supply chain can create for customers and shareholders. Commercial leaders need to understand the intricacies of supply, and supply chain leaders need to intrinsically know their customers. From my perspective, the only way to really gain this understanding is to experience it.

SCN: It is relatively rare these days to find manufacturers that produce their own products. Why has 3M bucked the outsourcing trend?

PK: 3M’s business model has four fundamental strengths: technology, manufacturing, global capabilities and the 3M brand; it is the intersection of these four components that create our “magic.” We employ these strengths across our company. For instance, in supply chain our proprietary process technology and manufacturing scale support the lowest unit costs in most of our categories. Our global capabilities support uniformly high quality and service levels, enabling us to better serve global customers. And our iconic brand supports pricing reflective of the higher value that our products provide, which further contributes to our industry-leading margins. Our supply chain is a significant competitive advantage for us. If we were to outsource manufacturing, we would be walking away from some of this advantage.

“Our supply chain is a significant competitive advantage for us. If we were to outsource manufacturing, we would be walking away from some of this advantage.”

SCN: At a recent shareholder meeting you spoke about the importance of footprint optimization. Can you say more about this?

PK: We operate a global supply chain of more than 200 plants and 100+ distribution centers. As we all know, handoffs create the potential for fumbles. Our footprint optimization effort is all about minimizing these handoffs. For example, we know that our largest plants, on average, are as much as 40 percent more productive than our smaller facilities. In the same way that larger plants are more efficient from a cost perspective, they tend to enjoy roughly 15 percent faster inventory turns as well. The same phenomenon holds true with our distribution centers where our larger, regional DCs, enjoy lead times 20-25 percent faster than smaller, local operations. Footprint optimization enables us to concentrate activity in our most capable operations, which generates productivity and velocity that support growth.

SCN: How do you encourage a culture of innovation within your supply chain organization?

PK: 3M is an innovation company. Innovation is central to our company’s vision, our strategies, and the leadership behaviors by which we measure our people. So, when it comes to creating a culture of innovation in supply chain, we greatly benefit by the overall culture of innovation within our company.

A good example is our fifteen percent culture. We encourage our people to set aside 15 percent of their workweek for unstructured, informal, self-directed experimentation. Because 3M is such a highly process-driven company, we believe it is important to have deliberate mechanisms that also provide the flexibility to be creative. An innovation culture is a necessary foundation, and we’re continually investing in it. Every year, we invest more than 10 percent of revenues back into innovation. About half of this goes into new product development, and about half goes into supply chain technology.

A good example is our fifteen percent culture. We encourage our people to set aside 15 percent of their workweek for unstructured, informal, self-directed experimentation. Because 3M is such a highly process-driven company, we believe it is important to have deliberate mechanisms that also provide the flexibility to be creative. An innovation culture is a necessary foundation, and we’re continually investing in it. Every year, we invest more than 10 percent of revenues back into innovation. About half of this goes into new product development, and about half goes into supply chain technology.

“We encourage supply chain team members to set aside 15 percent of their workweek or workday for unstructured, informal, self-directed experimentation.”

SCN: Talk about the ways in which you believe the intersection of supply chain and business transformation can create differentiated value for 3M customers.

PK: For us, Business Transformation starts and ends with our customers. BT is a network of mutually reinforcing systems, processes, and organizational structures. Supply Chain is interwoven into each of these components. For example, we are deploying a common systems backbone that provides end-to-end visibility which simplifies and accelerates decision making. Supply Chain is central to this because we are home to roughly half of the company’s data. In addition to deploying a common systems architecture, our transformation roadmap is also harmonizing key global process – common front-end interfaces like sales districting, CRM, eCommerce; and common back-end processes so critical to supply chain effectiveness and efficiency. Supplier management, capacity planning, network optimization are all good examples.

The benefits of common systems and processes are amplified through organizational structures that leverage these strengths. We have Business Services Operations that provide a unified front end to our customers. We have Global Service Centers that streamline back-office transactional activity. And we have Centers of Expertise that streamline and simplify our supply chain operations, “control towers,” if you will, that ensure smooth traffic flows across supplier management, manufacturing, logistics, etc.

The intersection of these systems, processes, and structures has had an enormously positive impact on our supply chain. For example, across EMEA where all three components have been deployed, COGS are down 170 basis points while customer service is up 90 bps.

SCN: With the deployment of advanced/disruptive technologies like IoT and robotics throughout supply chain organizations, more “traditional” approaches like Lean Six Sigma are less commonly discussed. Why do you think LSS remains such an integral part of 3M’s supply chain strategy?

PK: Lean Six Sigma plays two vital roles in our company – it is how we deliver business results and it is key to how we develop our people. This is important because the two are arterially linked at 3M. You can’t become a big leader in our company without delivering results; and as a company, we can’t consistently deliver results without big leaders. To illustrate just how important this is for us, almost half of our executive leadership team have completed formal black belt or master black belt assignments and pretty much all of us are green belt certified.

3M has a long track record of financial performance. We are one of a small handful of original DJIA component companies who are still part of the index, and part of an even smaller cohort with 100 straight years of dividend payments. We are also frequently cited amongst the world’s best companies for developing leaders. Lean Six Sigma is central to both. I can understand how some might view this as “old school,” but if so, it’s a moniker we wear with pride.

SCN: 3M was recently named a “Top Dream Company” for millennials. Talk about some of the programs/incentives you have specifically to attract young talent into 3M’s supply chain organization.

PK: To be honest with you, this recognition is more an outcome of perspiration rather than inspiration. We work very hard at attracting and developing talent at all career stages. But we have had a special focus on undergraduate or graduate recruiting lately, so it is gratifying to know that our efforts are making a difference. Millennials are as diverse as any demographic group, so it’s risky to generalize. Several of my millennial colleagues at 3M, though, are interested in making a difference in the world. I think that aspiration resonates well at 3M. For instance, “Improving Every Life” is the final stanza in our company’s vision statement. These are much more than just words on a wall. They really express what we aspire to achieve as a global enterprise.

Professionally, our millennials actively engage in designing, and re-designing their own careers. 3M provides fertile ground for doing this. Our 25 businesses serve a broad spectrum of the global economy. You can start in Health Care if that is your passion, working with pulmonologists to battle respiratory disease for example, and then completely change environments and work with global automotive OEMs, for instance, to help them reduce vehicle emissions. At 3M, you can have many different job experiences without ever changing your email address.

Across 3M you’ll find a wide range of programs attractive to young talent, like our Visiting Wizard STEM program, where we go into neighborhood schools and share the magic of science. Specific to supply chain, we have a development program targeted at millennials called Optimized Operations (O2). We recruit the brightest from some of the top schools around the world and we advance them through a series of cross-functional experiences. Leadership development, I think, accelerates with diversity of experience. We rotate the O2’s though different plants, different functions, different industry groups. Several key leaders in our company are graduates of this program.

Across 3M you’ll find a wide range of programs attractive to young talent, like our Visiting Wizard STEM program, where we go into neighborhood schools and share the magic of science. Specific to supply chain, we have a development program targeted at millennials called Optimized Operations (O2). We recruit the brightest from some of the top schools around the world and we advance them through a series of cross-functional experiences. Leadership development, I think, accelerates with diversity of experience. We rotate the O2’s though different plants, different functions, different industry groups. Several key leaders in our company are graduates of this program.

SCN: In recent years, supply chain sustainability has evolved from a “corporate branding” device to a means to support the “triple bottom line” (people, planet, profit). 3M received a 9/10 from Gartner for your CSR efforts. Talk about some of the programs that you are most proud of.

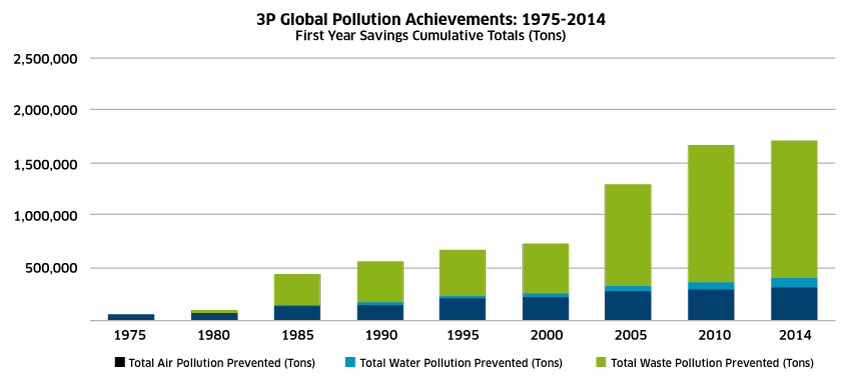

PK: As much as anything, 3M is recognized as a leader in CSR today in large part because sustainability has been a top priority for us for decades. In 1975, we established a program called “Pollution Prevention Pays” (3P), focused on eliminating pollution at its source. Our 3P maps well to the 3 P’s you mention – people, planet, and profit. Over the past 40 years, tens of thousands of 3Mers have been actively engaged in the program. Together, we’ve prevented over 2 million tons of pollution. And we’ve generated over $2 billion in savings for our customers and shareholders. We are a ten-time Energy Star winner and we’ve been a member of the Dow Jones Sustainability Index since its formation.

“We’ve prevented over 2 million tons of pollution. And we’ve generated over $2 billion in savings for our customers and shareholders.”

Our sustainability activities span our end-to-end value stream, starting at the very beginning with materials coming out of the earth, and spanning all the way downstream to how they are consumed by our customers’ customers. As an upstream example, we’ve partnered with The Forest Trust, a non-profit organization with a strong track record of responsible pulp and paper sourcing. Together, we are engaged across our supply chain to trace 3M materials back through mills to original forest sources. As a downstream example, we work with our customers to help them achieve their Sustainability goals. Last year alone, our products and technologies helped customers avoid 15 million metric tons of CO2. By 2025, this impact will grow to 250 million tons.

While environmental responsibility is an important part of our CSR activities, our responsibilities go beyond “just” operations. Twenty years ago we began publicly committing to specific sustainability objectives related to raw material management, water usage, climate and energy, health and safety, and education and development. Guided by these commitments, we’ve given back approximately $1.5 billion to our communities, we’re a signatory member to the United Nations Global Compact, and we’ve been named one of the World’s Most Ethical Companies by Ethisphere three years running.

SCN: Any final thoughts?

PK: At 3M, we have a strong continuous improvement culture. We’re continually deepening our understanding of our own operations. At the same time, we’ve found that we learn even more from working with customers, suppliers and peers. We’re a fairly curious group, so we invite all SCN readers to reach out to discuss topics of mutual interest. We may not have all the answers, but we’d love to work together to try and figure them out!