Lockheed Martin Weaves Digital Thread into Intricate Tapestry

From the launch of the first satellite into space in 1957, mankind has been transfixed by the mysteries that lie within the deepest reaches of the universe. While advances in technology, materials and machining have taken us farther into the heavens than most ever would have expected possible, it seems aerospace, defense and space systems maker Lockheed Martin has only just begun pushing the proverbial outer limits.

For the past three years, Lockheed Martin has been building and fine-tuning a fully integrated, end-to-end digital environment that is fundamentally transforming the way the company designs, sources, makes, moves, stores and services products. Weaving together three key digital domains—virtual reality, 3D printing and digital product support processes—Lockheed Martin has created a unique “Digital Tapestry.”

Rick Ambrose, executive vice president of Lockheed Martin Space Systems, a division of the $45 billion aerospace and defense manufacturer, describes the Digital Tapestry as “a seamless digital environment driven by an integrated model-based engineering (MBE) tool set that keeps the digital data intact from product conceptualization to realization.” This digital environment is supported by state-of-the-art information technologies and advanced manufacturing techniques, including 3D modeling, virtual reality simulation, Big Data analytics, 3D printing and automated inspection and testing.

The convergence of these technologies has taken Lockheed Martin beyond the realm of incremental performance, cost and cycle-time improvements, to designing and producing parts and systems that would literally be impossible to build using traditional design and manufacturing techniques.

PEAQ Performance

It’s a designer’s dream; but the Digital Tapestry is not just an engineering triumph. It is a truly cross-discipline success story, in which the company’s supply chain organization also plays a leading role, according to Mike Cacheiro, vice president of global supply chain, Lockheed Martin Space Systems.

“Supply chain is a huge part of the Digital Tapestry process because we represent about 60 percent of the spending for Space Systems,” Cacheiro said. “The Digital Tapestry allows us to operate in an interconnected environment that breaks down barriers both between various internal stakeholders and externally with our supply chain partners.” This enables Lockheed Martin to ensure that as a new product is being conceived, inputs from engineers, manufacturing and supply chain are all incorporated, yielding an end product that is functionally superior without being excessively complex to build or maintain.

The Space Systems division maintains a supply chain network of over 1,500 first-tier suppliers, 200 transportation providers and a product catalog of over 60,000 items, including many highly regulated parts and materials. The three guiding principles of the supply chain organization are program execution, affordability and quality (PEAQ).

In order to leverage the opportunities this digital environment offers to increase operational agility, improve supplier quality management, gather real-time performance metrics and provide end-to-end product traceability, the Space Systems supply chain team has been working in parallel with the development of the Digital Tapestry to upgrade its tools and processes, Cacheiro said.

The Digital Tapestry allows us to operate in an interconnected environment that breaks down barreiers both between various internal stakeholders and externally with our supply chain partners.

Enhanced digital connectivity to its supply base enables Lockheed Martin to minimize the amount of interaction required for non-value-added processes and to bring the supply chain closer to the product development process, promoting greater agility and drive toward part and process commonality. The Digital Tapestry includes a procure-to-pay (P2P) e-invoicing portal, electronic design records and a virtual catalog of standard components, subsystems and software modules that designers can plug into the simulations to see how they can help make products more sustainable or get them to market faster. One of the near-term goals is the development of an internal interface that allows Space Systems the ability to manage and monitor supply chain activity real-time to remain proactive and mitigate risk.

Trust, But Verify

But, as the company works to break down communications barriers within its supply chain, it has been equally important that they maintain—if not bolster—the security and integrity of these supply chain connections.

To that end, the Space Systems’ supply chain group has leveraged their existing Exostar aerospace and defense global access management interface. It is being used as a gateway to provide key suppliers with access to the company’s internal SAP system, via a two-factor authentication process, to update lead time and inventory cycle time information. This gives the manufacturing and production personnel real-time visibility to updates on critical parts.

Because cyber security is a “commandment-level” priority for Lockheed Martin, according to Cacheiro, a comprehensive cyber security questionnaire is a required part of the Trading Partner Manager registration in Exostar. The questionnaire provides the company with an indication of a supplier’s ability to protect sensitive information, which, in turn, allows the company to make more informed decisions on how to better manage risk.

Pushing the Digital Envelope

Pushing the Digital Envelope

True to its pioneering heritage, Lockheed Martin is actively involved in a number of initiatives to promote advanced manufacturing and materials innovations, including the Digital Manufacturing and Design Institute and the National Network for Manufacturing Innovation. Lockheed is also part of a project team that was recently awarded funding from America Makes, the National Additive Manufacturing Innovation Institute, for a development project designed to deploy the next generation of AM technology into a low-cost industrial multi3D system for 3D electronics manufacturing.

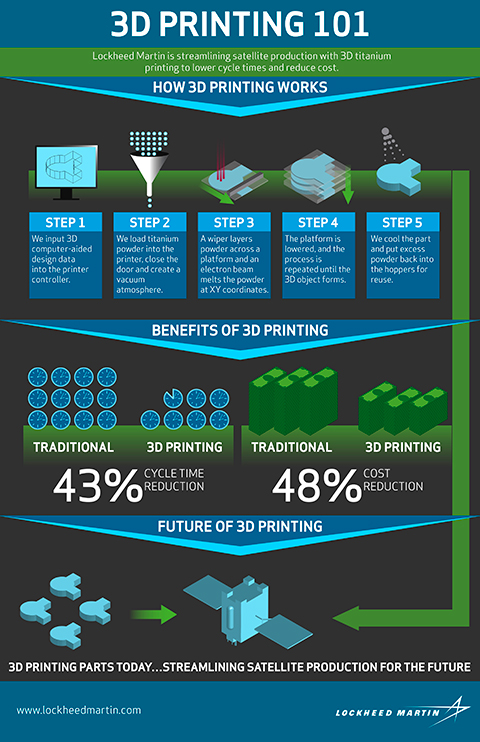

“We are looking forward to the day when we can transmit the design for an entire satellite to a manufacturing machine and print the entire satellite all in one piece,” Cacheiro said. “We are, of course, years away from that; but with the dramatic improvements in 3D printing capability occurring every six months or so, we are seeing it move up the adoption curve very quickly.”