Lenovo’s Prescription for Supply Chain Success

While many businesses today are still evaluating the potential to leverage supply chain and big data analytics to gain greater supply chain visibility, the strategy has been an imperative for Lenovo Group Ltd. since 2010, according to Mick Jones, vice president of Global Logistics and Supply Chain Strategy at the Beijing-based PC maker.

At the time, Lenovo was at a crossroads. The company was becoming far more complex due to acquisitions and the expansion of its products lines. The competitive pressure was compounded by the ambition of chairman and chief executive officer Yang Yuanqing to turn Lenovo into a truly multinational force in the electronics industry.

Gerry Smith, president of the Americas Group and executive vice president the Enterprise Business Group in Lenovo had already set a challenge to the teams to focus on the customer outcome of the supply chain and was driving hard from the top to create the customer-centric supply chain. As a result, Jones and his colleagues in the global supply chain team were being challenged to not only accelerate domestic growth with a faster and more cost-effective supply chain, but to also lay the groundwork for Lenovo’s expansion by strengthening its global supply network.

Mick Jones, Lenovo

To do so, Jones recognized that his team needed to shift its concentration from more traditional cost-reduction activities to focus on the “real value” in the business—creating a differentiated and superior customer experience. Data would be the key to unlocking that value. “There was so much data flowing through the organization, it became clear that if we did not find a way to use it to achieve the visibility we needed to make our business more flexible, responsive and customer-driven, we would be putting ourselves at a competitive disadvantage,” he recalled.

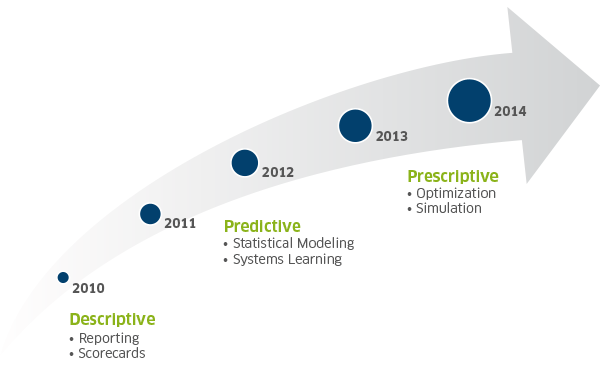

Evolution of Lenovo’s Analytics Roadmap

While some supply chains may be tempted to relegate the supply chain data analytics undertaking to the IT function, Lenovo believed that approach was not wholly the case. “This is not an IT owned project,” Jones said. “IT is not responsible for visibility and the core of analytics is about the business. Supply chain must be responsible, because it will own the outcome. Effectively it is led by SC, but tight collaboration with IT is essential for its success.”

The first step for Jones and his team was to better utilize the data already resident in Lenovo’s supply chain systems. “We started just trying to figure out how we could use the tools we had, like Excel, to drive productivity by improving reporting and dashboards,” Jones said. He noted that instituting a more aggressive data analytics strategy does not have to be a total wipe clean of current systems and process. “There is more that you can do with Excel, I think, than most companies realize. I have seen absolutely brilliant network designs done on nothing but an Excel spreadsheet. Sometimes, all you have to do is look at your data differently and apply a little bit of logic.”

A turning point for Lenovo’s global supply chain group was using its growing analytics capability to support the Perfect Order Fulfillment (POF) metric.

Instituting a more aggressive data analytics strategy does not have to be a total wipe clean of current systems and processes.

At the same time, Jones recognized that just focusing on data would not provide an accurate picture of the customer experience. “One of the dangers with analytics is that we start down this route of relying on numbers and we forget the qualitative aspect of what we are doing, but the qualitative and quantitative cannot be separated.”

The challenge is how to quantify qualitative measures and allow them to be a piece of data within the analytics formula. “That is definitely the more complicated part,” Jones noted. “What we try to do is convert the voice of the customer into things like accurate invoicing and reported defects in packaging and delivery process, which you can measure.”

The sophisticated data management and analysis tools of Lenovo’s state-of-the-art Data Analytics hub in Singapore and its new Corporate Analytics team, have also enabled the company to use both structured and non-structured data to tackle significant business issues, such as improving the company’s order-to-delivery times.

One of the dangers with analytics is that we start down this route of relying on numbers and we forget the qualitative aspect of what we are doing.

Using its predictive analytics capabilities, the team discovered that it was not a logistics breakdown, as one might naturally assume, but actually a days of inventory issue. “Orders were coming through, but there wasn’t adequate supply to fulfill them.”

Exposing this one problem then led to the identification of several contributing factors: supplier partners were occasionally missing their delivery dates into the manufacturing plants; parts failed quality tests and couldn’t be used; required days of inventory were miscalculated by Lenovo’s procurement managers. So, that initial piece of analysis drove a number of improvement projects that have enabled Lenovo to reduce inventory, improve cash flow and improve brand loyalty.

On the logistics front, increased visibility and supply chain intelligence has helped the company to improve air completeness from 85 percent to 95 percent and ocean completeness from 50 percent to 75 percent in just one year. In addition, reporting and process efficiencies derived from the increased visibility have resulted in a 10 percent reduction in labor hours while annual growth in PC shipments has increased an average of 13 percent.

The next major milestone for Lenovo, said Jones, is to establish an “intelligent” control tower. “Most control towers are very operationally driven, we’d like to get to the point where we are managing that operation with end-to-end visibility and at the same time dynamically defining where value is or could be,” Jones concluded. “Then using the data flowing through that process to, for example, dynamically schedule the direction we want to move in. So we won’t just be pushing product through the supply chain, but directing it through.”