Digital Solutions Drive Greater Sustainability Throughout Supply Chain

Supply chains become ever more complex and global, while at the same time, the spotlight on transparency and innovation around Corporate Social Responsibility (CSR) is shifting to the supply chain. Regulations and laws demanding supplier due-diligence are expanding, from the UK Modern Slavery Act and EU conflict minerals, to France’s Devoir de Vigilance bill and related laws in the US and elsewhere. These trends are exposing even more potential risks to brand reputation like supply disruption and increased costs or volatility. This is creating a “triple-whammy” of imperatives for procurement teams – and their trading partners – to monitor and manage risk, while at the same time exposing new sources of value that will be the key differentiators in the future.

But assessing and monitoring the CSR practices of suppliers worldwide poses tough challenges for procurement teams.

- Geographic diversity – Large multinationals’ supply bases often span 100 countries, each often, with differing laws and regulations, in dozens of languages

- Breadth – Supply bases cover hundreds of purchasing categories, each posing a different mix of CSR risks and issues

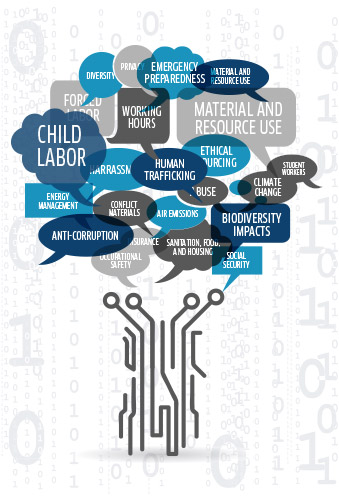

- Depth of criteria – There is a deep spectrum of CSR criteria to cover, including environmental, human rights and social issues; ethics and fair business practices issues, such as anti-corruption/anti-bribery; and how those business partners are monitoring their own supply chain

Often when procurement teams implement these programs internally, they must acquire or develop new resources, tools, and expertise in CSR and supplier engagement. This also poses challenges for suppliers, such as redundant surveys from each client; questionnaires that are often not adapted to their business category, size or location; a lack of context for understanding their performance relative to others or how to set expectations; or the absence of feedback and guidance needed to drive improvements.

Technology will play a key role in scaling up global CSR initiatives by helping to engage more of the 40+ million companies on the planet.

The solutions to these challenges are beginning to emerge through a potent mix of expertise and digital technology. Here are some areas of advancement that digitization will bring to bear:

- Scalability: Internal supplier CSR monitoring initiatives are often focused on engaging a few hundred vendors. Technology will play a key role in scaling up global CSR initiatives by helping to engage more of the 40+ million companies on the planet.

- Continuous Improvements: Traditional compliance approaches are often based on one-off audits. Digital technologies enable real-time monitoring of performance and measure ongoing progress on key sustainability indicators.

- Dynamicity: Supply chains are highly dynamic as vendors and contracts change constantly; this is growing exponentially if you look at Tier 2 or further levels up the supply chain. Technology solutions are emerging to help maintain and map both the commercial relationships and the sustainability impacts as these relationships shift.

- Transparency & Traceability: New technologies, such as “Block Chain,” can track the provenance of goods throughout the supply chain from raw materials to factories, laborers and logistics; and through branding and distribution. Additional data, such as sustainability indicators, can be attached at each step in the chain.

- Big Data: The diversity and volume of sustainability information being made available through social media, labor unions, environmental watch groups, and other NGO’s are also generating mountains of data. This creates a huge opportunity to mine this data, and to analyze and map it against spend data to derive real-time insights that guide better business decisions, as well.

- Open Networks and Apps Platforms with API Integration: These are connecting data, such as monitoring indicators from the supply chain, with apps to integrate into and improve procurement functions. Examples include using sustainability scores in apps for supplier financing, sourcing and RFX functions, and having a “live sustainability KPI leaderboard” to stimulate improvements.

Digital technologies enable real-time monitoring of performance and measure ongoing progress on key sustainability indicators.

We are eager to see how these new trends in digitization will drive sustainable supply efforts forward and help procurement teams with tangible benefits. Operational examples include reducing the risk of supply chain disruption, protecting brand reputation, and lowering costs; e.g., collaboration on packaging reduction. On a strategic level, by identifying the best suppliers to invest in and innovate with, they can help build supplier relationships that give the purchasing organization a competitive advantage.

Related Resources:

- Report: Beyond Compliance – The 5 Pillars of sustainable procurement value creation

- Podcast: Procurement Plays Vital Role in Reducing Global Warming

- Interview: Mondelez to focus on traceability and sustainable production

- EcoVadis CSR Scorecard (Sample)

- EcoVadis Targeted Guidance for Supply Chain, 2015