An Inside Look at Flex’s Risk Management Framework in Action

How applying various supply chain resilience levers helped us persevere amid Covid-19 disruptions

By Lynn Torrel

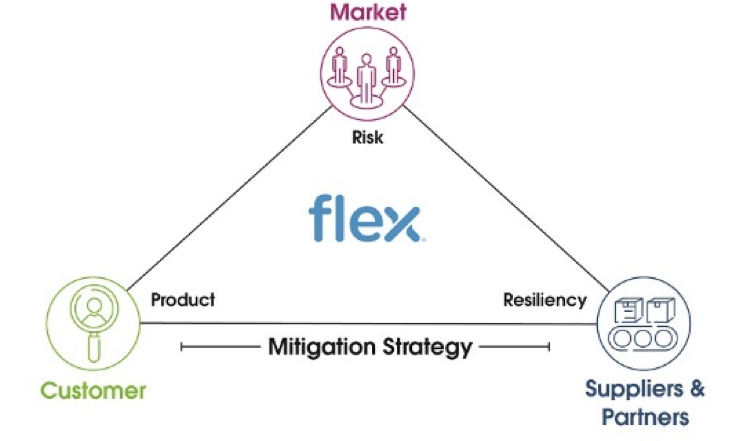

As an organization managing some 1,000 supply chains on our customers’ behalf, Flex is constantly evaluating our risk mitigation models. We identify, evaluate and mitigate risks through three lenses:

Serving our customers: Understanding our obligations to customers requires an understanding of the risks in the chain. This begins with identifying the most critical components and mapping out their associated risks. For example, are there seasonal shortages of critical parts or potential price fluctuations that we need to plan for?

Taking the pulse of our suppliers and partners continuously: How financially stable are our partners? Are there emerging risks to quality and timely shipment?

Keeping tabs on potential marketplace disruptions: These include political, environmental and other external threats.

Operationalizing Visibility, Flexibility and Collaboration

Building a strong supply chain is a proactive de-risking process that never ends. Like any insurance policy, it comes with a cost. With your core goals and resources driving your investment decision, there are multiple tools and tactics at your disposal. This table shows how various risk mitigation strategies could be applied across our three pillars.

| Visibility and velocity | Flexibility and agility | Collaboration and relationships | |

| Customers | Understand the shifts that can disrupt your processess and production such as changes to your customer’s product demand forecast and launch plansIdentify critical components, their lead times and any specialized tooling required for custom parts. | Build Supply buffers of mission critical parts by stocking extra inventory.Configure facilities for nimble production which can be designed in a way to shift product mix quickly. | Be a genuine partner to your customer and stay current on the developments in their business and markets. This extra effort will allow you to have meaningful conversations and information sharing. |

| Suppliers and partners | Audit preferred first-tier suppliers for financial health, ESG standards and other relevant attributes. | Develop dual- or multi-source supply base.Understand suppliers’ product lifecycle plans to get ahead of discontinued parts. | Build on your customers’ exsisting relationships with suppliers.Strengthen supplier relationships through ongoing engagement such as site visits and regular check-ins. |

| Market | Analyze data from many sources to build a wide-ranging view of realtime market risks.At Flex, we use Flex Pulse, a realtime dashboard that ingests data from hundreds of external and internal sources to give us a realtime view. We draw on wide-ranging data sources that include our purchase order systems to third party weather forecasts. | The growing complexities in our world require risk mitigation models on multiple fronts.Line up alternative suppliers in different geographies to mitigate the effects of tariff wars and other trade disruptions. | Build relationships with organizations having visibility and expertise in domains that matter to your business. This includes research firms and givernment agencies. During COVID, the information we got from government officials helped us make decisions in a highly dynamic environment. |

Designate Teams and Assign Accountability

With the risk mitigation plans in place, it is critical to ensure accountability throughout your organization. At Flex, we have a company-wide global resilience team tasked with diffusing risks in the event of serious threats and large-scale interruptions. This team prioritizes the protection of Flex assets and those of our customers and partners which include human resources and intellectual property.

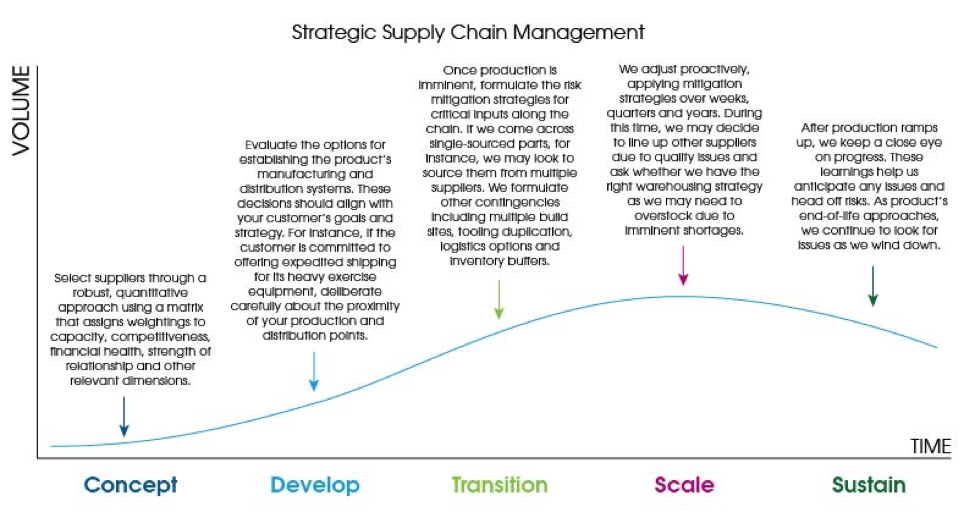

When it comes to the particulars of a specific product line, these are managed by a strategic supply chain team that oversees all related operations. As the first line of defense when issues arise, this team constantly assesses risks and collaborates closely with planning, procurement and other teams to optimize operational shifts and decisions specific to addressing the product and customer needs.

Specifically, the strategic supply chain team analyzes the risk profiles of the key inputs along the product’s lifecycle from beginning to end.

Resilience in Action

How do all of our advance preparations play out in real life? During the COVID-19 crisis, Flex received early warnings from our team in China. Utilizing dashboards in our Flex Pulse system, we wasted no time in taking action. Our global resilience team immediately engaged as the ground-zero command and control center. By instinct, collaboration became the order of the day. Our China teams guided us through pandemic risk reduction best practices, including how often to change masks and how to sanitize and deep clean our factories.

In parallel, we set up war rooms around the world hosting executive meetings every day. This cascaded into many follow-up conversations and action items with cross-functional teams worldwide to identify solutions around the clock.

Tiger Teams on the Prowl

My organization, along with the resilience team and other cross-functional peers, held global daily calls. Our first priority was to understand all the parts originating from China, and freeze the current order status, ensuring no open orders were pushed or cancelled. To gain visibility into the actual supply and demand, we then reconfirmed forecasts with customers and orders with suppliers to verify that what was on order was still required by customers and produced by suppliers. Everyone pitched in and the information became visible and actionable via Flex Pulse real-time dashboards.

Once we sized up supply and demand the best we could, we needed to figure out how to move the parts to meet production schedules then deliver the finished goods. Through this highly fluid situation where we were operating on imperfect information, I wanted to hear everyone’s voice. We had many daily discuss-debate-decide moments in rapid succession as the number of decisions required each day stretched over 12 to 16 hours at the height of the pandemic.

Overcoming Challenges Through Agility and Strong Relationships

During this time shortages became an issue, and this hit our healthcare solutions group particularly hard. The team went from experiencing normal shortages for around 25 parts in late January to shortages of hundreds of parts within weeks. Some relief came by way of the strong collaborative relationships we have established with our suppliers over many years, which enabled us to dramatically reduce the replenishment cycle for certain key parts while securing commitments for continuous shipment.

For other critical parts in short supply, we had standing workarounds. For instance, we had engaged our engineers to identify and test viable substitution parts during the pre-production design and tooling phase. Taking this extra step meant we were ready to source the substitute parts – and this proved to be a worthwhile investment during the COVID-induced shortages.

For other critical parts in short supply, we had standing workarounds. For instance, we had engaged our engineers to identify and test viable substitution parts during the pre-production design and tooling phase. Taking this extra step meant we were ready to source the substitute parts – and this proved to be a worthwhile investment during the COVID-induced shortages.

Our decision-making capability was enhanced by information our teams were able to glean from our network of relationships which also includes government bodies who gave us insights into the pandemic’s trajectory and potential border closures.

Bringing together internal and external stakeholders and their multi-domain expertise put us on an agile and decisive path to problem-solve at scale.

Looking Back and Looking Forward

Resilience is not about investing in a single tactic or technique; instead, it is a proactive process that continuously incorporates new learnings. In this vein, consider building a roadmap for making your COVID-19 lessons actionable. What insights have you gained into your chain’s weakest links that you can leverage to help you be better prepared for the next disruption? What are the critical investments to make in light of these weak links?

At Flex, we saw the payoffs from our investments in building strong foundations and contingencies that helped us adapt to the challenges resulting from the pandemic. Is our supply chain bullet proof? Certainly not. Supply chains will never be completely risk-free – the key is to install the right talent, infrastructure, tools and culture to achieve business continuity and to continuously identify opportunities to fine-tune your risk management practices.

This article was adapted from a blog post originally published on Flex.com.

Related Resources:

- Video: How Procurement is Pivoting Through the Pandemic While Continuing to Provide Business Value

- Video: Flex 2020 Virtual Supplier Summit

- Article: Digital Tools Help Businesses Keep Watch for Faulty Connections in Supply Chain

- Podcast: Women in Electronics Radio – Lynn Torrel “Leader in Highlight” Interview